-

Phone: 0086-15858860365

-

Email: sales1@nswvalve.com

-

Phone: 0086-15858860365

-

Email: sales1@nswvalve.com

News

-

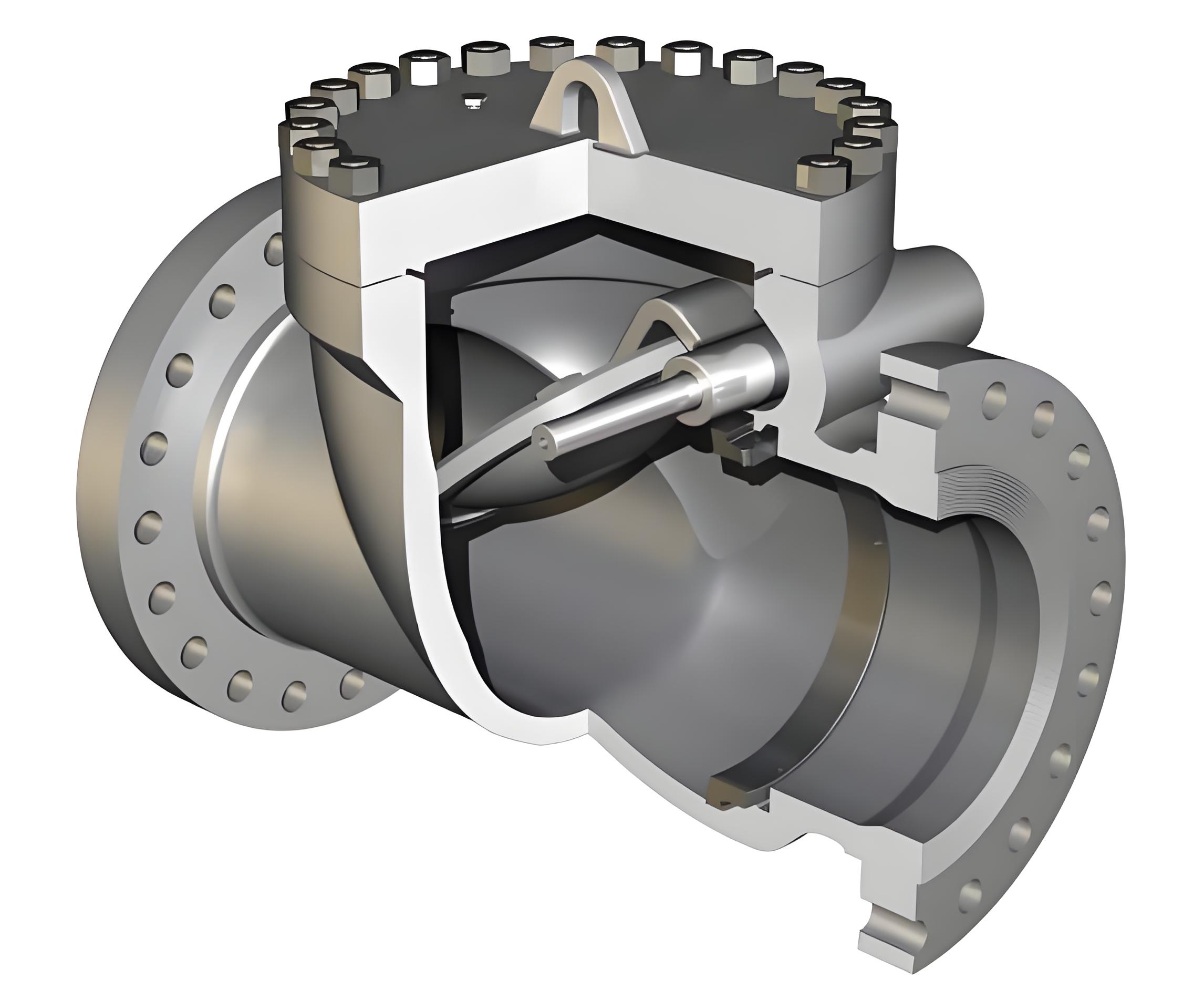

Introduction to the principle of check valve

Check valve, also known as check valve, check valve, its working principle is mainly based on the automatic opening and closing of the valve disc to control the one-way flow of the medium and prevent backflow. The following is a detailed introduction to the working principle of the check valve: F...Read more -

What are the types and specifications of check valves

Check valves are available in various types and specifications according to factors such as structural form, material and application. The following is a detailed summary of check valve types and specifications: First, type 1. Classification by structure Lift check valve: A check valve with a dis...Read more -

Check valve function

The check valve is an automatic valve whose main function is to prevent the backflow of media in the pipeline. The following are the main functions of the check valve: 1. Prevent media backflow: The core function of the check valve is to ensure that the medium (such as water, gas, steam, etc.) ca...Read more -

What are the installation methods of check valves?

The installation method of check valve is mainly determined according to the type of check valve, the specific requirements of the pipeline system, and the installation environment. The following are several common check valve installation methods: First, horizontal installation 1. General requir...Read more -

What is a Check Valve: Ultimate Guide of Type and Standard.

Check Valve Overview A check valve is an automatic valve that uses fluid pressure and disc weight to prevent reverse flow. Also known as a non-return, one-way, reflux, or isolation valve, its core function is ensuring unidirectional flow to protect piping systems from backflow damage. How Check ...Read more -

Does the ball valve need maintenance?

Ball valves do need maintenance. Ball valves are key components in the field of fluid control, and their normal operation and long life cannot be separated from regular maintenance and maintenance. The following are several important aspects of ball valve maintenance: First, check regularly 1. S...Read more -

Ball valve internal structure

The internal structure of the ball valve is relatively simple and well-designed, mainly composed of the following key components: First, the sphere Function: As a ball valve opening and closing parts, the middle of the ball with a channel, through rotation to control the media on and off. Materia...Read more -

The function of ball valve is introduced

As a common type of valve, ball valves play an important role in industrial and civil fields. Its main functions can be summarized as follows: First, cut off and distribute the medium Cut off the flow: The ball valve controls the flow path of the medium by rotating the ball, and when the ball is ...Read more -

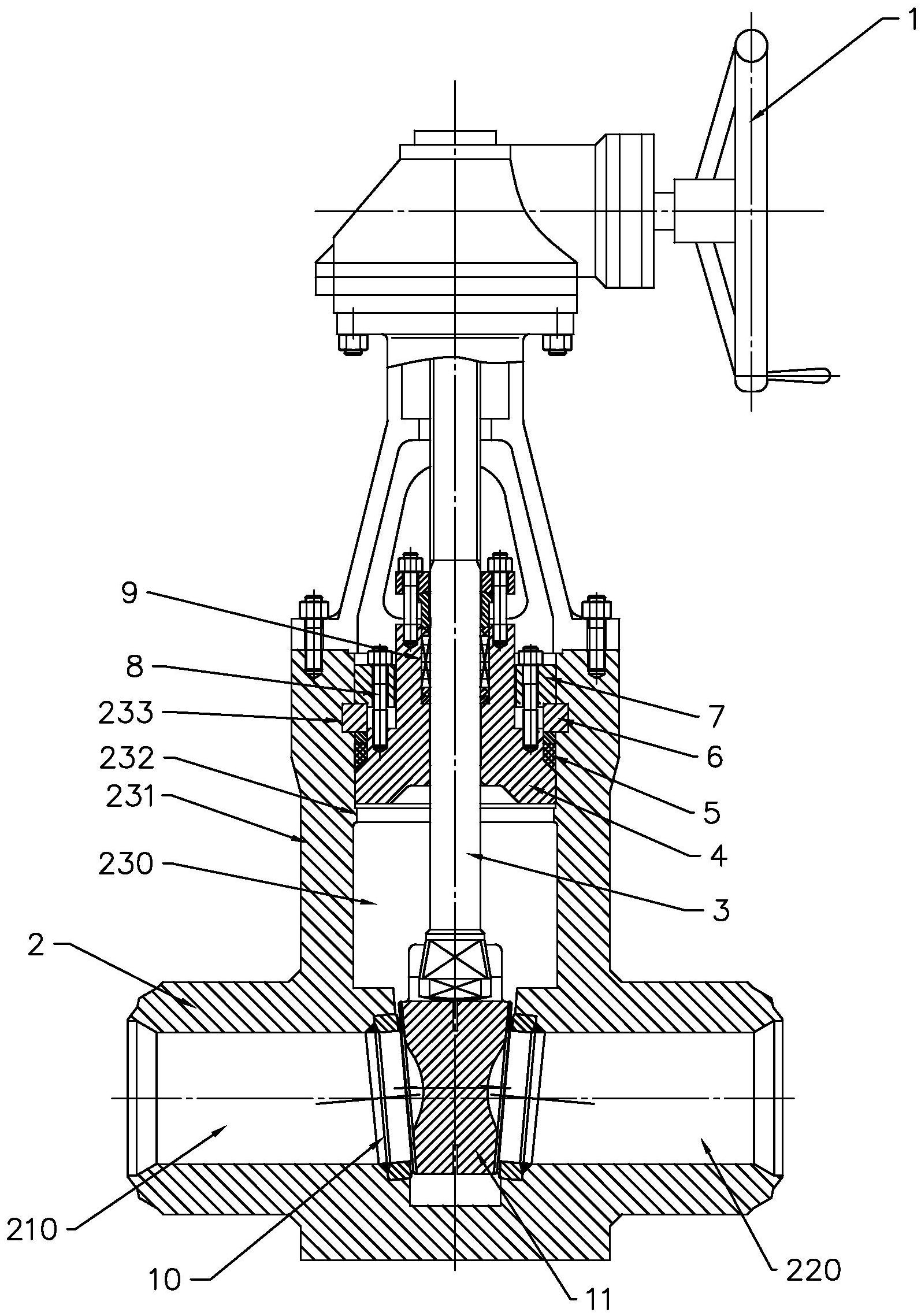

What are the Top 10 Gate Valve Manufacturers in the world

Leading Global Suppliers: 2024 Industry Benchmarks Our 2024 ranking of the Top ten gate valve manufacturers leverages comprehensive network data analysis, verified sales metrics, and brand reputation evaluation. This curated list empowers industrial buyers to identify trusted valve suppliers with...Read more -

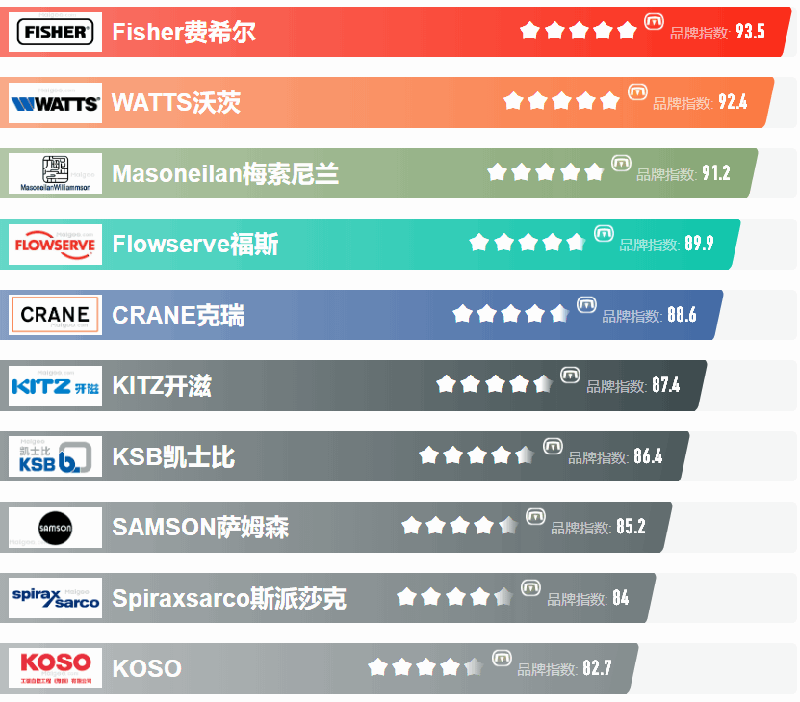

What are the top 10 ball valve manufacturers in the world

Do You Know the Top 10 Ball Valve Manufacturers in the World The list of the Top Ten Global Ball Valve Brands has been released after professional evaluation. The top ten are: NSW, Fisher, WATTS, Masoneilan, Flowserve, CRANE, KITZ, KSB, SAMSON, Spiraxsarco, KOSO, etc. The top ten valve brands and...Read more -

What are the maintenance methods of ball valves?

Read more -

What is the difference between ball valve and gate valve

Ball valves and gate valves are two common types of valves, and they have significant differences in structure, working principle, and use scenarios. Here’s a breakdown of the differences: First, structural differences 1. Ball valve: - Spool: The ball with a hole in the middle is used as t...Read more -

Ball valve structure introduction

Ball valve is a common type of valve, its structure is relatively simple and powerful, widely used in a variety of fluid pipeline systems. The following is a detailed description of the ball valve structure: First, the main components Ball valve mainly consists of the following parts: 1. Sphere:...Read more -

How to avoid ball valve leakage problems?

To avoid the occurrence of ball valve leakage problems, you can start from the following aspects: First, choose the right ball valve 1. Select according to the characteristics of the medium: When selecting the ball valve, the nature of the medium, such as corrosion, temperature, pressure, etc. s...Read more -

How to solve the ball valve leakage problem?

What is a ball valve leakage Ball valve leakage refers to the phenomenon that liquid or gas leaks inside or outside the valve body during the use of the ball valve. Ball valve is one of the commonly used valves, and its leakage problems are mainly divided into two types: internal leakage and ex...Read more -

Ball valve common fault introduction?

As an important component of fluid control, ball valves may encounter some common failures during long-term use. The following is an introduction to the common faults of ball valves: First, leakage Leakage is one of the most common failures of ball valves and can be caused by a variety of reason...Read more -

What are the maintenance methods of ball valves?

Ball valve maintenance methods mainly include the following steps: First, fault diagnosis and preparation 1. Phenomenon observation: First observe the operating status of the ball valve, and pay attention to whether there is leakage, jammed or inflexible operation. 2. Preliminary inspection: Che...Read more -

Ball valve installation method?

The installation method of the ball valve needs to be determined according to the type of the ball valve, the characteristics of the pipeline and the specific use environment. Here are the general installation steps and precautions: First, prepare before installation 1. Confirm the pipeline stat...Read more